Molded Fiberglass

Overview

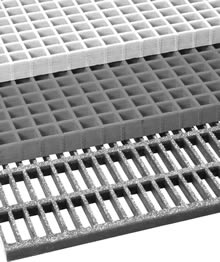

Molded Grating combines fiberglass rovings with thermosetting resin to form a strong one-piece molded panel. There are seven types of resins available, each offering different levels of corrosion-resistance and fire retardancy to meet your specific needs. Consisting of 65% resin by weight, molded grating offers superior corrosion resistance. Additionally, outstanding slip resistance for worker safety is provided by the standard concave meniscus surface or with optional surfaces of Quartz or Aluminum Oxide Grit.

Square Mesh pattern allows for easy on-site cutting of panels, allowing a variety of flooring layouts to be easily accommodated with minimal waste. The need for additional supports is eliminated in many cases due to this product’s bi-directional strength.

Rectangular Mesh offers one-direction span strength in the width of the grating panel and is often used for walkways and trench covers.

Please see our “Molded & Pultruded Comparison Chart” to determine whether

square or rectangular mesh best suits your application.