Other Brown-Campbell Products

Abrasive Coatings

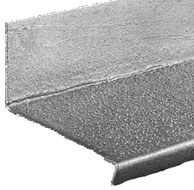

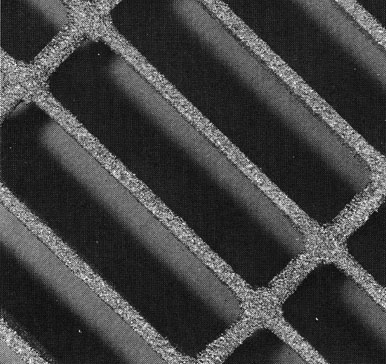

Abrasive Coatings applied to specialty metal products offer superior slip resistance. Our abrasive coatings have a surface hardness of up to 62 on the Rockwell “C” scale. This approaches the hardness of a file and gives our abrasive coatings the longest wearing surface of any slip resistant product offered. The bond strength exceeds 4,500 p.s.i. Surface hardness and bond strength are critical to longevity. Low bond strength allows the surface to wear off, dramatically reducing the slip resistance and therefore, effective life.

Why use Abrasive Coatings?

- Limits liability exposure due to injuries resulting from slips and falls.

- Exceeds all OSHA standards for safety and slip resistance.

- USDA/FDA approved for use in the food service industry.

- Cleans Easily

- Long lasting, Durable, and Economical

- Versatile: Can be applied to any product

- Modifiable: Any fabricaton can be applied without adverse effects

- Weldable: Can be directly welded to with no surface preparation.

A fine surface with minimum surface depth suitable for variable pedestrian traffic flow and areas with moderate liquid accumulation.

A fine surface with minimum surface depth suitable for variable pedestrian traffic flow and areas with moderate liquid accumulation.

A medium surface applicable to heavier liquid accumulations. This is considered the all-purpose surface.

A medium surface applicable to heavier liquid accumulations. This is considered the all-purpose surface.

A coarse surface applicable for extremely heavy traffic, higher debris accumulation and high viscosity fluids.

A coarse surface applicable for extremely heavy traffic, higher debris accumulation and high viscosity fluids.

Abrasive Coating Process

All metal plasma stream disposition applied directly to plate, bar grating, stair treads, ladder rungs or other specialty steel product. Our abrasive coating can be fabricated in any way (punched, sheared, torched, plasma or laser cut, welded, etc.) on the surface or underside without any adverse effects to the abrasive coated surface.

Applications Include...

- Walkways

- Conveyors

- Platforms

- Stairs

- Bridge Walkways

- Wheelchair Ramps

- Ladder Rungs

- Vehicle Surfaces

- Assembly Lines

- Tank Bottoms

- Vault Covers

- Engine Rooms

Plate

Plate Stair Treads

Bar Grating