Pultruded Fiberglass

Overview

Pultruded Grating is manufactured with a high percentage of glass within the laminate, providing durability, extremely high unidirectional strength and stiffness. Due to its exceptional stiffness, pultruded grating can be used in applications requiring wide support spans, rarely needing additional support.

To form a pultruded element, continuous fiber rovings and mat are mechanically drawn through a resin bath and shaped through a series of forming guides, then pulled through a heated die.

Pultruded grating exceeds the requirements for grating used in chemical, water and wastewater, electronics, food and beverage, pulp and paper, petroleum processing, and marine applications.

Corrosion resistant • Long life • Maintenance-free • Lightweight • Easy to Fabricate Easier to install • Slip-resistant • Non-conductive • Fire retardant

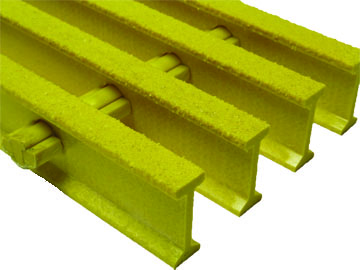

Pultruded I-Bar Fiberglass Grating

I-6000 and I-4000 Series

• Superior and economical walking surface

• 60% and 40% open areas

Pultruded Heavy Duty I-Bar Fiberglass Grating

I-5800 and I-4700 Series

• High strength designed specifically for heavy loading and to support vehicular traffic

• 58% and 47% open areas

Pultruded T-Bar 1" & 1-1/2" Fiberglass Grating

T-3500, T-1800 and T-0000 Series

• Most comfortable walking surface

• 1” & 1-1/2” Height: Solid surface, 35%, and 18% open areas

Pultruded T-Bar 2" Fiberglass Grating

T-5000 and T-3300 Series

• Most comfortable walking surface

•50% and 33% open areas